1-Chloropentane: A Comprehensive Commentary

Historical Development

Chemists began looking for new alkyl halides in the nineteenth century to explore organic synthesis and fuel emerging industrial processes. 1-Chloropentane, also called n-pentyl chloride, entered lab notebooks as synthetic routes evolved to harness simple hydrocarbons. By the early twentieth century, researchers improved chlorination methods and found that straight-chain alkyl chlorides like 1-chloropentane served as versatile building blocks for further chemical transformations. The push for larger hydrocarbon resources during the petroleum boom of the 1940s and 50s put compounds like 1-chloropentane on procurement lists—sometimes for small-volume syntheses and sometimes as models to help understand reaction mechanisms. I’ve often seen it mentioned in older texts as a handy reference for chain-length studies or as a test substrate when exploring nucleophilic substitutions. Over the years, demands shifted from lab-scale prep to batch production to suit demands in pharma, agrochemicals, and solvent development, with purity levels and handling practices getting stricter along the way.

Product Overview

1-Chloropentane brings a five-carbon backbone with a single chlorine atom at the terminal position. It’s more than just a piece of chemical trivia—it’s a practical intermediate that helps chemists introduce straight chains and test the behavior of haloalkanes under different reaction conditions. In pharmaceutical labs, I’ve seen it considered for use in the preparation of specialty amines, or as a reference material for chromatography due to its predictable retention behavior. Its clear, colorless liquid form and distinctive odor make it easy to recognize, but also call for careful storage since volatilization can cause unwanted exposure in lab spaces. Bulk manufacturers supply it in drums or glass containers, emphasizing tight seals and protection from heat or light exposure. Unlike many aromatic or branched halides, 1-chloropentane’s structure keeps it physically simple but still reactive enough to help make more valuable molecules for agriculture, fragrance, or solvent research.

Physical & Chemical Properties

1-Chloropentane presents as a colorless liquid, with a boiling point around 107°C and a melting point near -93°C. Its density hovers around 0.87 g/cm³ at 20°C, comparable to other medium-chain alkyl chlorides. This compound does not dissolve in water but mixes well with most organic solvents, including ether, alcohol, and benzene. It flashes readily at lower temperatures (flash point near 15°C), so keeping open flames or sparks far from storage areas makes sense. Those who’ve handled it in fume hoods know the telltale sharp, ether-like odor. Chemically, 1-chloropentane undergoes typical nucleophilic substitution and elimination reactions, offering a window into basic organic mechanisms and serving as a substrate for exploring both alkylation and dehydrohalogenation.

Technical Specifications & Labeling

Quality control sets the thresholds for purity at levels frequently exceeding 98%, checked by gas chromatography. Labels on commercial bottles or drums list the CAS number (543-59-9), hazard pictograms indicating flammability and acute toxicity, and recommended storage temperatures (usually between 2–8°C or “cool, dry, well-ventilated area”). Technical specifications often provide IR and NMR spectral data, refractive index (about 1.408 at 20°C), and residue limits for acid, water, and sometimes specific halide contaminants. Safety datasheets include handling guidelines that require splash goggles, gloves resistant to chlorinated hydrocarbons, and strong ventilation. It’s common in my experience to see packaging in amber or opaque glass—less about photosensitivity, more about accident prevention and preserving chemical stability.

Preparation Method

In industry and research labs, synthesis of 1-chloropentane most commonly follows the free-radical chlorination of n-pentane, often using UV light or elevated temperature in the presence of chlorine gas. These processes demand precise control to limit formation of di-, tri-, or poly-chlorinated by-products. On a smaller scale, chemists often convert 1-pentanol to 1-chloropentane using thionyl chloride (SOCl₂) or phosphorus trichloride (PCl₃) in anhydrous conditions, sometimes with a base like pyridine to neutralize side acids. These conversions provide decent yields, but require well-ventilated fume hoods because of HCl or SO₂ by-product release. My own experience confirms that controlling moisture and temperature pays off, since side reactions can make purification tricky. Distillation under reduced pressure remains the go-to for obtaining pure product after synthesis.

Chemical Reactions & Modifications

The simplest transformation for 1-chloropentane is nucleophilic substitution (either SN1 or SN2 depending on reaction conditions and nucleophile). It readily yields pentanols, pentyl ethers, or pentyl thiols, depending on the nucleophile involved. Treating it with aqueous KOH or NaOH leads to 1-pentanol, while alcoholic bases cause elimination, producing pentenes. I've found that such reactivity makes this molecule valuable for didactic work in undergrad labs—students can observe first-hand how substitution and elimination compete. Alkylation with ammonia or amines allows chemists to prepare various pentylamines, which are intermediates in pharmaceuticals and agricultural chemicals. Grignard reactions using 1-chloropentane and magnesium in ether yield pentyl magnesium chloride, a useful reagent for further carbon-carbon bond formation.

Synonyms & Product Names

1-Chloropentane goes by several names, including n-pentyl chloride, pentyl chloride, and primary amyl chloride. CAS 543-59-9 acts as the universal tag in catalogs, making cross-referencing straightforward. Various suppliers list it under synonyms tailored to certain applications, like “chloropentane,” but structure-based names (primary, normal, or n-pentyl) dominate in technical documentation and research literature.

Safety & Operational Standards

Routine handling of 1-chloropentane demands robust safety practices. Direct contact irritates skin and eyes and can harm the respiratory system if inhaled in even modest amounts. Storage containers need to be sealed tightly, with fire-proof cabinets recommended due to the low flash point. Proper labeling and chemical segregation from oxidizing agents or strong bases protect against reactive incidents. I recall colleagues strictly enforcing the use of nitrile gloves and splash protection whenever decanting or sampling this chemical. Emergency protocols for spills emphasize quick containment, ventilation, and use of absorbent inert material—plus prompt disposal according to hazardous waste guidelines. Proper training and thorough access to updated safety data sheets remain foundational for any facility using or storing even moderate quantities of chlorinated alkanes like this one.

Application Area

1-Chloropentane’s usage centers on intermediate synthesis—a stepping-stone in creating pharmaceuticals, agrochemicals, and specialty surfactants. Chemists employ it as an alkylating agent to introduce a five-carbon chain into molecules, or as a standard for chromatographic measurements. Organic labs often call on it in test reactions or mechanistic studies to evaluate nucleophilic substitution and elimination ratios. Specialty syntheses, such as flavor or fragrance components, sometimes specify 1-chloropentane because it opens up access to pentyl-substituted aromatics or alcohols. Small quantities occasionally show up in materials research, helping to model solvent effects or as a precursor for surfactant production. End-users favor 1-chloropentane for its predictable reactivity and manageable storage requirements, making it easier to scale up alkylation steps or introduce well-defined carbon chains.

Research & Development

In research environments, 1-chloropentane serves as a case study for chain-length effects in halide chemistry, reaction kinetics, and solvent system development. Analytical scientists use it to calibrate gas chromatography systems and interpret mass spectra. As synthetic strategies trend toward greener reagents and milder conditions, chemists continue searching for catalytic, less-toxic conversions of alcohols to chlorides. Research groups look to improve selectivity in chlorination processes or develop one-pot conversions that reduce solvent and energy costs. Toxicological researchers keep examining metabolic pathways and breakdown products, spurred by growing concerns about occupational and environmental exposure to chlorinated alkanes. I’ve observed graduate students running simulations on chlorinated intermediate formation and seeking proprietary processes to minimize hazardous by-products, driven by stricter environmental regulations and waste disposal mandates.

Toxicity Research

Toxicological studies link short-chain alkyl chlorides, 1-chloropentane included, with acute inhalation and skin exposure risks. Symptoms like headache, nausea, or respiratory distress crop up quickly in poorly ventilated labs, a situation not uncommon in older facilities. Chronic exposure data remains more limited, but researchers investigate the compound’s metabolism and potential for bioaccumulation or carcinogenicity. Animal studies highlight moderate toxicity, with liver and kidney impacts flagged at higher doses. The chemical breaks down into hydrochloric acid and pentanol or pentenes in the body, and concerns about environmental persistence remain, especially if large spills reach water sources. Tighter workplace exposure limits, regular air monitoring, and personal protective equipment reduce risks, but ongoing monitoring and epidemiological studies help clarify long-term health impacts. Labs using it for research take precautions, but I see opportunities to improve air handling and waste management practices—practices that help protect both staff and the surrounding community.

Future Prospects

The demand for 1-chloropentane looks steady, aided by its importance as a synthetic intermediate and test substrate. As chemical manufacturing pivots to greener and more sustainable routes, producers seek replacements for traditional chlorination methods, aiming to cut down on toxic by-products and energy use. Digital process monitoring, improved containment, and real-time emission tracking offer routes to safer, more efficient operations. Advances in catalytic conversion, using milder reagents and recyclable solvents, could transform the way chemists make and use alkyl chlorides across the board. Researchers continue probing metabolic impacts, environmental fate, and breakdown products—work spurred by evolving regulatory landscapes that tighten acceptable emissions and workplace exposure limits. New applications, including materials science or next-generation surfactants, could broaden the molecule’s reach, provided downstream impacts are managed responsibly. For the people who handle or encounter 1-chloropentane, attention to evolving best practices and emerging scientific findings will keep this chemical both useful and as safe as humanly possible.

Getting to Know 1-Chloropentane

Anyone who has dabbled in chemistry labs has run into solvents and reagents that seem like background players. 1-Chloropentane fits that bill for most folks, yet it quietly powers a lot of important processes. The clear, colorless liquid gives off a sharp, sweet odor that is hard to forget. For those of us who once spilled a beaker or two, that scent sticks in memory. Behind that smell, though, sits a chemical compound with more roles than many outside lab circles realize.

How Labs and Factories Use 1-Chloropentane

Chemists and workers in manufacturing settings pull out bottles of 1-Chloropentane for its ability to help stitch carbon atoms together. In the lab, it’s often a starting material for building more complex molecules. Want to create longer-chain hydrocarbons or design new pharmaceuticals? This chemical helps carve out the basic framework. That matters, because a lot of everyday products—think medicines, agricultural treatments, or specialty plastics—rely on these chemical backbones.

As an alkylating agent, 1-Chloropentane joins carbon chains with other groups. By adding the five-carbon chunk to everything from drug molecules to synthetic lubricants, chemists can tweak how substances behave. Performance upgrades in coolant fluids or even some fuel additives sometimes trace back to small changes made possible by this simple compound.

Importance in Teaching and Research

Many undergraduates meet 1-Chloropentane during their first organic synthesis lessons. The molecule’s clear reactions make it ideal for illustrating core chemical concepts. Watching it react in nucleophilic substitution helps students see how swapping-out basic elements reshapes a molecule. These lab demos build the hands-on experience needed to work safely and efficiently with more dangerous or sensitive chemicals in later years.

Health and Environmental Realities

Like many halogenated hydrocarbons, 1-Chloropentane demands respect in the lab and on the production floor. Skin contact leads to irritation, and inhaling too much vapor can knock a person off balance. Personal stories from older chemists sometimes include tales of careless glove use—or worse, vapor headaches from poor ventilation. These days, industry standards push for proper labeling, improved ventilation, and careful disposal.

Runoff or improper disposal of 1-Chloropentane poses environmental challenges. Its chemical structure can persist in soil and water, trickling into bigger ecological issues if left unchecked. That’s one reason why safe chemical management has become a talking point in both public and private sectors. Using closed-system manufacturing, stricter storage regulations, and community take-back programs offers real-world ways to keep this compound from turning up where it shouldn’t.

Looking Forward

There’s an opportunity for further progress in green chemistry. Researchers in universities and private companies work on ways to swap out chlorinated compounds like 1-Chloropentane for safer alternatives, or at least to recycle and reuse these materials more efficiently. This effort builds on the success stories from labs that have reduced waste by rethinking reaction pathways or shifting to less hazardous reagents.

By remembering the lessons of the past and paying attention to evolving best practices, the scientific community can keep harnessing the usefulness of 1-Chloropentane—while keeping people and the planet safer. For anyone working in a lab or nearby, knowing this chemical’s role makes it easier to respect both its power and its pitfalls.

Getting Real About Chemistry in Daily Life

Chemistry class often felt like some far-off place with little to do with daily routines or career paths. Yet, understanding molecules and how they behave matters far beyond lab benches. Take something like 1-chloropentane. It isn’t just a name you memorize and forget. Its molecular formula carries practical weight—shaping paths in manufacturing, pharmaceuticals, and even the perfumes on store shelves.

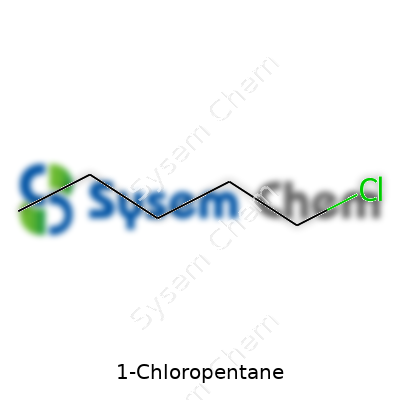

Decoding the Details: What Is 1-Chloropentane?

This compound looks simple—one chlorine atom replaces a hydrogen on a straight-chain hydrocarbon called pentane. Pentane means five carbons lined up, each with enough hydrogens to fill out its valency. Swap a hydrogen for chlorine at the 'first' carbon, and you’ve got 1-chloropentane. This gives us the formula C5H11Cl.

Why Molecular Formulas Matter

A molecular formula isn’t just textbook information. In industries that use solvents or chemical intermediates, manufacturers have to know the composition down to each atom. One extra chlorine or a misplaced carbon alters how the compound acts—its toxicity, its odor, even its flammability. In my own work, small details like this dictated success or failure in scaling up a reaction from beaker to batch.

Mistakes cost money and time. The wrong formula on a label means redoing weeks of work, burning up budgets, and sometimes putting workers at risk. That’s how 1-chloropentane’s formula connects far beyond blackboards and test tubes. Getting it right builds real trust with customers, regulators, and all those folks who use final goods.

Real-World Applications and Concerns

Chemists and engineers use 1-chloropentane as a building block. This compound slips into processes that make pharmaceuticals, cleaning fluids, and solvents. Small manufacturers rely on its predictable structure. Larger companies care about sourcing and environmental health.

Even one spill in a facility handling chlorinated hydrocarbons influences environmental policy. Regulatory agencies like the EPA and Health and Safety Executive keep a sharp eye on compounds like 1-chloropentane, not because they distrust science, but to avoid polluting air and water. The molecular formula gives clues about volatility and persistence in the environment, which guides decisions about ventilation and waste disposal.

Ongoing Challenges and Solutions

Plenty of chemical education still skips teaching why formulas like C5H11Cl should matter in the workplace. Textbooks overflow with formulas but rarely explain why someone manufacturing hand sanitizer or specialty coatings must pay attention. Companies could start here by showing how accuracy reduces hazards, lowers insurance premiums, and keeps reputations intact.

Modern labs now use digital systems to cross-check formulas and inventory. Still, mistakes slip through. The most effective solution brings together good training and clear communication. Employees not only memorize formulas—they understand how a single misprint changes everything. I learned fast that talking through these molecular details with new team members improves confidence and reduces the learning curve.

Looking Forward

Getting familiar with the molecular formula for something as specific as 1-chloropentane opens bigger conversations. These details power safer plants, sharper product labeling, and transparent supply chains. Small steps taken to teach and double-check the basics strengthen whole industries and, ultimately, protect the people behind every bottle, batch, or barrel.

Putting 1-Chloropentane Under the Microscope

Some chemicals rarely make headlines, and 1-chloropentane sits quietly on lists of organic compounds used in labs. As a colorless liquid with a faintly sweet smell, 1-chloropentane slips through many chemistry courses without much attention. Its place in the chemical world comes down to its role as a building block—an alkyl halide useful for making more complex molecules. This background might distract from a bigger question: Is it hazardous or toxic?

Not Just a Lab Curiosity—Potential Hazards in Everyday Contexts

The facts tell a straightforward story. Breathing in 1-chloropentane vapors can irritate the nose and throat, even cause dizziness or nausea. Liquid exposure brings its own problems—skin absorbs halide solvents more easily than water, so direct contact should be strictly avoided. Eye exposure can cause stinging and redness, and nobody wants to end up in an emergency room over a careless splash.

I spent years working in a chemical analysis lab, where solvent stains on the counter triggered more stories than spills. Chlorinated solvents like 1-chloropentane earned their own spot in the chemical storage room—away from acids, bases, and oxidizers. Once, a co-worker spilled a few drops on the floor. The sharp, suffocating smell told us all to step back and turn on the ventilation right away. Even experienced chemists don’t shrug off chlorinated organics.

Toxicity on Paper and in the Real World

Data from safety datasheets and agencies like the US EPA show that 1-chloropentane is no joke. Swallowing even a small amount can bring on symptoms like headache, fatigue, confusion, or loss of coordination. High exposure over a longer time could hurt the liver or kidneys. Sometimes, those effects only show up after several days.

Acute toxicity numbers (LD50) for 1-chloropentane sit in the "moderate" range, meaning it takes a few grams per kilogram of body weight to be deadly in rats. That might sound like a lot, but chemists never take those numbers lightly. Chronic exposure studies haven’t been as thorough as for famous solvents like chloroform, but some evidence suggests long-term handling without protection might raise cancer risk. Regulators in Europe and North America keep sounding the bell: proper protection means gloves, goggles, and a working fume hood, with no exception.

Practical Hazards Out in the World

Manufacturing, transporting, or storing chlorinated solvents always brings environmental worries. A spilled drum or leaky container can let the chemical seep into soil or groundwater. Chlorinated hydrocarbons resist breaking down, so once out, they tend to stick around for years. Cleanup costs skyrocket once these solvents escape into the wild, and communities living near chemical plants keep a close eye on leaks.

Prevention, Training, and Responsibility

Solutions rarely come from a single checklist. Good safety standards—like regular training, up-to-date safety data sheets, and clear labeling—make a difference. Engineering controls, including fume hoods and proper ventilation, set the foundation. Emergency response plans keep people and the environment safer if a spill does happen.

Simple rules, followed every time, keep everyone safer around 1-chloropentane. Don't let familiarity breed carelessness. Respecting the hazards, staying updated on regulations, and speaking up if something seems off—these steps protect people and the environment in ways that no warning label ever could.

Why Storage Matters for Chemical Safety

Over the years, I’ve watched chemicals shift from something handled by a trained few to being ordered online and found in home labs or small workshops. 1-Chloropentane sits in that group of solvents and reagents with real risks that fly under the radar. It doesn’t get the headlines of acids or heavy metals, but it’s volatile, flammable, and can harm people with careless storage. Anyone who’s opened a cabinet to smell that potent, sweet scent knows things aren’t being stored right. Leaking 1-chloropentane can go from a minor nuisance to a full-scale hazard—both at work and at home.

Understanding Volatility and Reactivity

This liquid evaporates fast on a warm day, and that vapor is heavier than air. In a poorly ventilated room, it hugs the floor and creeps toward a pilot light or an unsuspecting electrical outlet. Once, I saw an old drum of solvent left by a loading dock in midsummer. By night, the fire department had blocked the street off. An easy mistake, but one that forced an evacuation.

So, storing 1-chloropentane means treating it with care. Leave open bottles, and the vapor wins. Store it above hot pipes or in the sun, and you invite pressure buildup. Most labels remind you: keep it cool, dry, and away from sparks. I don’t mind repeating such advice, since too many people skip them.

The Basics: Containers, Temperature, and Location

Glass or metal containers with airtight seals work best. Polyethylene won’t do, since 1-chloropentane can soften it and cause leaks over time. Labels need to stay clear and legible—no scribbling with fading marker. The ideal storage spot? A chemical cabinet that’s ventilated, shaded, and far from any ignition sources. Forgetting to ground metal storage cabinets or letting rags soaked in solvent pile up turns an average facility into tomorrow’s news story.

Check storage temperatures: don’t keep it above room temperature. A simple thermometer and a max-min sticker often save a world of hurt. Damage from sunlight not only degrades the compound but can heat up its container until it bulges or ruptures. Even sealed drums risk bursting under a direct sunbeam.

Keeping Water and Acids Out

Mix 1-chloropentane with acids or water and dangerous byproducts can form—hydrogen chloride comes to mind, and no one wants that in the air. I’ve always kept organics and inorganics separate. Cross-contamination starts silently, often at the end of a long day with misplaced bottles. Spill trays and locked cabinets cut the risk. Trained staff with good routines mean a single bottle mistake won’t ruin a month’s safety record.

Respect the Risks and Rules

It’s easy to overlook solvents like 1-chloropentane because they don’t shout danger unless you’re listening. Local regulations rarely cover every scenario, so practical knowledge fills the gap. Having current safety data sheets handy, using protective gear, and running regular storage audits do more than check boxes—they save property and lives. My time in university labs taught me that most accidents grow from shortcuts and half-remembered warnings, not villainous intent.

Treating storage as a living process, not a checklist, keeps people and places safe. That’s real respect for chemicals like 1-chloropentane, and for those of us who work around them every day.

A Glimpse into 1-Chloropentane

1-Chloropentane belongs to the family of alkyl halides. In a lab or industrial setting, you spot it as a colorless liquid that gives off a mild, sweet odor. The structure counts five carbon atoms lined up with a chlorine atom attached at one end. That simple arrangement plays a big role in shaping how this chemical behaves.

Boiling Point and Volatility

What jumps out about 1-chloropentane is its boiling point—around 107 degrees Celsius. This places it on the lower side for many industrial solvents, making it easy to convert into vapor with a little heat. When a chemical vaporizes with modest heating, safety gear and good ventilation become must-haves. I've seen labs underestimate the fumes from such liquids, leading to headaches or worse if the room fills up with vapors.

Density and Appearance

Pour 1-chloropentane into a beaker and notice that it looks pretty much like water. Its density clocks in at about 0.88 g/cm³, so it floats on top of water. This kind of lightness might sound harmless, but in the case of spills, it helps the chemical spread more quickly. If any leaks get into waterways, it won’t just sink and settle—it’ll linger on the surface, where it can travel far from the source.

Solubility: Water vs. Organic Solvents

1-Chloropentane and water don’t get along much. At room temperature, its water solubility stays under 0.5 grams per liter. This makes cleanup after spills harder because water-based solutions just push it around instead of dissolving it. On the other hand, this compound mixes well with organic solvents like ether, benzene, and alcohol. In the real world, I’ve seen researchers reach for such solvents during synthesis and extraction work. It’s a practical detail—chemists lean on good solubility to make reactions go smoothly, especially during separation steps.

Volatile Organic Compound (VOC) Concerns

1-Chloropentane falls into the category of volatile organic compounds. This classification gets regulators’ attention because VOCs can lead to ground-level ozone through chemical reactions in sunlight. As cities step up air quality rules, labs and factories have to keep closer tabs on their emissions. Simple changes, like installing capture systems or swapping in less volatile chemicals, can make a real difference in staying within legal limits and protecting public health.

Handling and Safety Implications

This compound may not strike fear like some of the heavier halides, but its volatility and low flash point mean it catches fire easily. Throughout my time in university labs, there were multiple fire drills sparked by leaks of similar, low-boiling-point chlorinated solvents. Always treat storage of 1-chloropentane like you would any highly flammable organic—use flame-proof cabinets, keep containers tightly sealed, and don’t let temperature climb. Gloves and splash-proof goggles become standard gear, as skin and eyes don’t appreciate even brief contact.

Reflections and Solutions

Working with 1-chloropentane highlights how a clear understanding of physical properties translates straight into safety and effectiveness in the real world. Switching to less volatile chlorinated solvents, adding spill containment plans, and improved air handling in workspaces help cut fire risks and minimize pollution. Even in resource-stretched settings, double-checking for leaks and controlling storage temperatures makes a large impact.

By paying attention to these basics, teams avoid the headaches—not just from fumes, but from regulatory trouble and cleanup bills—that come with ignoring the simple, physical truths about chemicals like 1-chloropentane.