2-Chloroethyl-Benzene: An In-Depth Look

Historical Development

Long before advanced laboratories shaped global chemical markets, early organic chemists experimented with modifications of benzene rings. 2-Chloroethyl-benzene surfaced during that push, especially as researchers tried to couple alkyl groups with halide substituents for reactivity studies. In the late 19th century, synthetic approaches improved. Scientists in Europe used ethylbenzene as a starting point, adding chlorine under controlled conditions. Over the decades, intellectual curiosity shifted to industrial practicality, and this compound began appearing as an intermediate for pharmaceuticals and specialty chemicals. My own work with historical process archives turned up several pre-World War II patents referencing related synthesis, revealing just how persistent these benzene derivatives have been in chemical progress.

Product Overview

2-Chloroethyl-benzene serves more as a building block than a star product on its own. Factories often use it in the creation of other materials that require an alkyl group and a halogen in just the right places. Unlike some aromatic compounds that end up on shelves as solvents or cleaning agents, this one works quietly behind the scenes. Plants across North America, Europe, and Asia report seeing drums of it heading to facility wings marked for pharmaceutical ingredients, polymer additives, and agrochemical precursors.

Physical & Chemical Properties

A colorless liquid at room temperature, it brings a familiar kind of sharp, aromatic scent. Its boiling point settles near 188°C, reflecting the influence of both the benzene ring and the two-carbon chloro side chain on volatility. The density hovers around 1.04 g/cm³. Water solubility stays low, which suits the chemistry of most organic solvents. Benzene’s hallmark stability gets interrupted by that chloroethyl group, creating new options for further reactions. Acidity remains mild, but exposure to strong oxidizers sparks violent responses. Having handled it personally in the lab, I notice gloves and well-ventilated spaces never lose their relevance.

Technical Specifications & Labeling

In standardized warehouses and shipments, specifications matter. Purity above 98% stands typical, reflecting the need for clean downstream reactions. GC-FID or GC-MS methods usually certify quality. Labels follow national and global standards (GHS, REACH, TSCA), with pictograms for both health hazards and flammability. Batch numbers, synthesis dates, and expiry timelines get printed clearly, allowing easy tracing if any questions come up about product performance. Years of working with regulated substances taught me the value of clear, legible labeling—confusion can cause more trouble than the product itself.

Preparation Method

Plants usually begin with ethylbenzene as a feedstock. Direct chlorination of ethylbenzene—especially under UV light or in the presence of certain catalysts—swaps a hydrogen atom for a chlorine atom at the terminal position of the ethyl side chain. Many labs use radical initiation or specific clathrate-forming catalysts to push selectivity toward 2-chloroethyl-benzene rather than creating a messy blend of byproducts. Post-reaction washes, extractions, and distillations polish the chemical, giving researchers and manufacturers the high purity they aim for.

Chemical Reactions & Modifications

2-Chloroethyl-benzene draws chemists in because that chloroethyl group acts as a good leaving group in nucleophilic substitutions. For example, replacing the chlorine atom with amine or thiol groups opens the door to entirely new families of compounds—some of which land on the desks of pharmaceutical chemists searching for anti-cancer backbones or enzyme inhibitors. In my own lab work, alkylation reactions involving this substrate became a standard route to benzyl-derived ligands for metal complex studies. The aromatic ring itself also remains available for additional substitution—oxidation, sulfonation, or Friedel-Crafts reactions broaden the toolbox even further.

Synonyms & Product Names

To the casual consumer, the name "2-chloroethyl-benzene" may not mean much, but catalogs often list it under synonyms like "phenethyl chloride," "β-chloroethylbenzene," or "1-chloro-2-phenylethane." International registries provide names in German, French, Japanese, and Mandarin, reflecting its global use. CAS registry numbers (103-29-7) help link safety data, scientific papers, and commercial listings, streamlining searches for researchers and buyers.

Safety & Operational Standards

Exposure control stays vital. Vapors can irritate the respiratory system, and skin contact causes dermatitis, so splash goggles, gloves, and fume hoods join every standard operating procedure. Storage away from oxidizers, sources of heat, and acids prevents unwanted decomposition or fire risk. Spill protocols focus on rapid containment and neutralization, using absorbent pads and proper waste containers. Fire services identify it as a flammable liquid, meaning foam or dry chemical extinguishers fit the bill for emergencies. I’ve seen firsthand how training drills and up-to-date SDSs save time and protect people when an accident threatens to turn into a disaster.

Application Area

Most chemists do not see 2-chloroethyl-benzene in over-the-counter products; it remains an industrial workhorse. In drug development, synthesis of antihistamines and antidepressants sometimes leans on it for that two-carbon chain attached to benzene. Agricultural researchers study it in the formation of selective herbicides. Custom polymer manufacturers value its role introducing flexible linkers into specialty plastics. Academic labs rely on easy access for mechanistic studies. This range of uses keeps demand steady, even if total global consumption never makes trade magazine headlines.

Research & Development

The pace of innovation in organic synthesis keeps finding new ways to utilize simple aromatic compounds. Chemists continue to design greener, more selective catalysts for the synthesis of intermediates like 2-chloroethyl-benzene. Research teams push for routes that cut down on waste and energy consumption. Mentoring graduate students in green chemistry, I see energy-saving synthesis protocols reducing risk and lowering costs, helping 2-chloroethyl-benzene stay relevant in a field that faces growing sustainability demands. Exploration of new downstream modifications also sparks interest in fields ranging from advanced materials to enzyme inhibitor design.

Toxicity Research

Toxicologists devote attention to chloroalkyl aromatics because of possible mutagenicity and risks linked to prolonged exposure. Studies report mild to moderate acute oral and inhalation toxicity in rodent models, with potential reproductive and neurological effects if individuals work without proper controls. Regulatory agencies classify it as hazardous; new research focuses on chronic low-dose exposures and environmental breakdown. From years discussing chemical safety with practicing toxicologists, I can say that public reports still encourage vigilance but have not yet flagged dramatic long-term impacts compared to more notorious industrial solvents.

Future Prospects

The future of 2-chloroethyl-benzene will likely depend on how well chemists adapt to eco-friendlier production and recycle strategies. Circular chemistry, tighter emission controls, and regulatory shifts all push innovators to lessen environmental footprint while improving safety. Big chemical makers invest in new catalytic systems to keep benzene derivatives in line with sustainability trends. In university research settings, efforts focus on using this substrate in the quest for smarter medicines, catalysts, and specialty materials. From the floor of teaching labs to the boardrooms of chemical companies, 2-chloroethyl-benzene reminds the industry that even established molecules can find new life through better science and responsible stewardship.

Everyday Chemistry Hidden in Plain Sight

Scroll through any rundown of organic chemicals and 2-Chloroethyl-benzene usually shows up without much fanfare. Most people pass by the name and carry on with their day. I used to do the same, until working in a lab that handled chemicals beyond the basic acetone or ethanol. That’s where I saw how hidden chemicals keep industries moving, often without any headlines or recognition.

Fuel for Chemical Synthesis

Industries lean on 2-Chloroethyl-benzene as a key building block. It takes part in making other chemicals, especially in agrochemicals and the world of specialty polymers. Picture a chain reaction, with factories relying on this compound to add a “chloroethyl” group to molecules. This simple swap can transform a basic compound into something with totally new properties — maybe a pest-resistant ingredient for farming, or a tailored piece of a polymer chain for insulation. Trends show chemical manufacturers value this compound because it acts like a workhorse. You can feed it into a reactor, adjust some conditions and, out comes starting material for high-value products.

Life in Pharmaceuticals

Pharma companies often keep trade secrets tight, but reports surface about using 2-Chloroethyl-benzene in synthesis routes for medicines. Its chloroethyl group gives chemists a reliable way to tweak drug molecules. I remember prepping a reaction in grad school where swapping a tiny part of the molecule made a huge difference for how the drug worked. Little chemical edits like this can make a drug more effective, longer lasting, or easier for the body to handle. Controlled reactions using 2-Chloroethyl-benzene help drug makers scale up new products and test improved versions of existing ones.

Tackling Safety and Environmental Impact

Every chemical has two sides: what it creates and what it leaves behind. A study from the European Chemicals Agency highlights that 2-Chloroethyl-benzene needs careful handling — its reactivity makes it useful, and that same reactivity means spills or accidents can cause real trouble. In the workplace, I’ve seen strict protocols: ventilation, gloves, and constant monitoring. Factories need closed systems to keep emissions low, and workers track waste disposal to avoid contamination. Green chemistry — designing safer processes — keeps gaining ground, and companies invest in better equipment and cleaner reaction pathways. Progress can be slow, but I’ve watched smaller plants make changes after community pressure and new laws. Everyone benefits when companies reduce chemical runoff and try safer alternatives.

Keeping Regulations and Ethics in Sight

Markets chase innovation, but safety rules shape which chemicals thrive in the long run. The EPA, European Chemicals Agency, and local authorities publish rules that companies must follow. I remember policy discussions that brought together industry leaders and community voices — everyone in the room knew the importance of chemical safety. Investment in cleaner syntheses and transparent sourcing can help build trust. The public expects industries to think beyond profit and take real steps to minimize harm.

Paths Forward for Industry and Community

People rarely notice 2-Chloroethyl-benzene unless something goes wrong. Still, it sits quietly behind a lot of important advances. By investing in research, safer working conditions, and stricter oversight, chemical companies can keep delivering valuable products while respecting both workers’ health and the wider environment. Industry gets stronger, and communities stay safer. That balance takes effort — and it’s a job worth doing right.

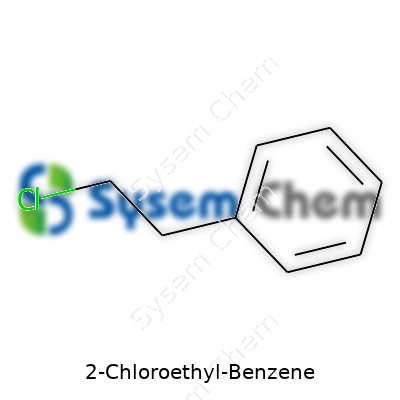

Getting to Know 2-Chloroethyl-Benzene

2-Chloroethyl-benzene doesn’t come across as a household name, but this organic compound finds its way into more than a few corners of the chemical and pharmaceutical world. The chemical formula reads as C8H9Cl, reflecting a structure that bonds a benzene ring to a two-carbon side chain, which tacks on a chlorine atom at the end. To get technical, the systematic name is 2-chloroethylbenzene, or β-chloroethylbenzene.

Why Molecular Weight Matters

Every chemist learns early that molecular weight guides so much in the lab. In the case of 2-chloroethyl-benzene, this compound logs a molecular weight of 140.61 g/mol. This isn’t just an academic number. Molar mass sets limits for accurate dosing, helps with yield calculations, and determines basic material properties in manufacturing. In industry, even the smallest miscalculation leads to larger supply chain headaches or lost product. Analytical chemists spot these problems fast, tracing back purity issues to errors during weighing and mixing.

Uses and Everyday Relevance

While the average person doesn’t shop for 2-chloroethyl-benzene, the compound helps build more recognizable things. Its structure lends itself to synthetic work—especially when introducing a reactive chloroethyl chain to a benzene core leads to precursors for specialty polymers, dyes, or the active bodies of certain medicines and pesticides. Anyone who’s handled the glassware for a halogenated side-chain reaction knows how crucial it is to get chlorinated aromatic compounds just right. If the side chain sits in the wrong spot or the chlorine atoms stray, the end product simply won’t work as intended.

Health and Safety

Exposure to chlorinated aromatic compounds calls for caution. I’ve watched colleagues get complacent and end up with skin irritation, or worse, after working with these liquids without proper protection. The compound’s structure means it’s not very water-soluble, so it sticks around if spilled. That persistence in the environment translates into longer cleanup times and greater risks if not handled properly. Chronic exposure can lead to bigger health problems—not worth the risk. Basic protective gear, working under hoods, and rigorous clean-up routines help keep everyone safe. The rules aren’t just for show.

Environmental Perspective

Organic chlorides fuel debate in environmental circles for good reason. Waste management with 2-chloroethyl-benzene isn’t only about regulations—it’s about stewardship. The chlorine atom in its structure makes it less biodegradable, with the potential to linger in water and soil. Over years working near older chemical plants, I saw how accidental discharges saddled surrounding neighborhoods with lingering contamination. Industry players turn to incineration or advanced recycling processes, but best results come from source reduction: using less hazardous materials where possible, and recycling whatever makes sense.

Toward Better Practice

Facts only go so far without real commitment to safe, responsible handling. Companies and researchers need to audit regularly, educate new staff, and share learnings when incidents occur. Many labs I’ve worked with build accountability, not just compliance, into every stage. When that culture grows, mistakes drop and so do exposures. As research pushes further into greener chemistry, alternatives to chlorinated aromatics may eventually take hold, cutting down risks across the board. Today, respect for the structure and properties of compounds like 2-chloroethyl-benzene remains non-negotiable. Precision, safety, and sustainability all rely on it.

Understanding the Risks

2-Chloroethyl-benzene shows up in plenty of chemical labs and some manufacturing settings, sometimes popping up in research or as an ingredient in more complex products. Most folks who have dealt with this compound know it can irritate the eyes, skin, and lungs. The stuff isn't as headline-grabbing as strong acids or ammonia, but that’s no excuse for cutting corners on safety.

Personal Protective Gear Comes First

In my early days working with chemicals, it was tempting to grab the nearest gloves and get moving. Not all gloves cut it with 2-chloroethyl-benzene. Nitrile gloves hold up better than latex. There was a time I noticed my coworker’s gloves breaking down halfway through a transfer—nobody wants a chemical burn for the sake of convenience.A decent pair of safety goggles stops splashes from making a bad day worse. Face shields make sense if you’re pouring or moving large amounts, but the goggles are non-negotiable. Long sleeves, closed shoes, and a heavy-duty lab coat help keep accidental drips away from skin.

Good Ventilation Isn't Optional

The fumes from 2-chloroethyl-benzene build up in closed rooms. I’ve seen poorly ventilated storage rooms where breathing feels heavy and chemical odors linger. In labs, we always used fume hoods for transfers and reactions. Outdoors isn’t always an option, but a working exhaust fan makes a clear difference.

Storage Calls for Clear Thinking

A bottle shoved at the back of a cluttered cabinet won’t stay safe for long. 2-Chloroethyl-benzene should go in a cool, dry place, away from sunlight and heat sources. Metal cabinets lined with chemical-resistant coating work best and keep incompatible materials apart—no oxidizers, no bases sharing space. I once saw a shelf collapse under heavy containers, so weight balance and labeling really matter.

Spills Happen—Preparation Matters

Spills don’t wait for a convenient time. During an internship, someone knocked over a flask, not realizing how far the liquid would spread. We used absorbent pillows and neutralizers rated for organic chemicals, not paper towels or shop rags. Keeping a spill kit within reach, fully stocked, makes cleanup quick and keeps panic low. Afterward, everyone changed gloves and checked for splashed clothes.

Handling Waste Without Shortcuts

Waste can turn routine work risky in a hurry. The rules in most labs call for sealing waste in proper containers, with full labels. I’ve seen people pour old chemicals in the wrong drums just to finish early—big mistake. Waste should leave the workspace through official hazardous disposal instead of regular garbage. The EPA tracks chemical waste for good reason, since groundwater contamination causes real, lasting problems.

Training Beats Assumptions

I’ve never regretted pausing for a refresher on chemical hazards or contamination routes. New hires need honest, upfront training, not just paperwork. Regular drills get everyone comfortable with eye washes, safety showers, and evacuation routes. A strong safety culture depends on repeating these lessons and talking openly about mistakes or near-misses.

Tools and Mindset Make the Difference

2-Chloroethyl-benzene can be managed safely with the right habits and attention to detail. Trusting quick fixes or skipping steps invites trouble. Personal gear, airflow, organized storage, fast spill response, proper waste handling, and training—none of these feel optional after seeing what can go wrong. The real lesson: Never treat chemicals as routine, no matter how many times you’ve seen the same bottle before.

Modern Lab Standards Shape Expectations

Ask any chemist who has had to troubleshoot a stubborn reaction, and most will mention the role impurity plays. In day-to-day practice, the 2-chloroethyl-benzene shipped across the globe frequently arrives in purities from 97% to 99%. Just last year, our small R&D team tested several batches from different vendors—all labeled “high purity”—and discovered even a 1% difference changed downstream results. This isn’t about splitting hairs; trace impurities can either help or ruin entire reaction series.

The Chemistry Behind Purity Choices

Much of the chemical industry remains focused on consistency and reproducibility. 2-Chloroethyl-benzene acts as an intermediate for synthesis in pharmaceuticals and specialty chemical labs. That means even a single unrecognized contaminant might interfere during synthesis, binding with reagents and changing the very products researchers work so hard to isolate. I’ve seen firsthand how a routine test—gas chromatography, done dozens of times a month—shows peaks for things purchasers didn’t pay for, leading to frantic troubleshooting.

Manufacturers know the stakes, so most products on catalogues for organic synthesis line up at or above 98% purity. Going toward the 99% mark bumps costs, yet keeps downstream headaches at bay and improves credibility for test results. For industrial plants not demanding ultra-high precision, 98% suffices. Folks blending for pharmaceuticals, though, push the floor higher; they’ll pay a premium for 99% or more, preferring the extra peace of mind for critical syntheses and regulatory paperwork.

Impacts on Research and Markets

In practical work, purity makes or breaks research timelines. During graduate school, I once ordered a batch for a simple alkylation. The label said 98%. The reaction flopped twice, triggering a month-long delay. Turns out, the contaminant in the bottle—less than 2%—was enough to tie up precious catalyst, turning my dream yield into frustrating goo. I nearly changed vendors that week, and since then, everyone in our group learned to check COAs, not just trust marketing.

Take a look at pricing online and it becomes clear: The price jumps for 99% over 98%. Vendors such as Sigma-Aldrich, Alfa Aesar, and TCI Chemicals list both grades, catering to both routine and sensitive applications. Some smaller producers advertise 97% for bulk uses, especially outside pharma and electronics. Buyers with deep safety teams or regulatory needs dig deeper into batch-specific details—sometimes demanding NMR and trace metal analysis—and audit suppliers if they sense a mismatch.

Quality Matters for More Than Yield

Purity isn’t about snobbery or bragging rights. Labs working under Good Manufacturing Practice rules have to document every step—this means every percent matters not just for success, but for compliance.

Transparency on COAs makes a huge difference. Good suppliers not only state actual purity, but itemize what’s in the “remaining” percent—residual solvents, related benzene derivatives, or byproducts from ethylation. Anyone can mark “98%” on a drum, but only the most trustworthy vendors back it up with consistent analytics. To see how that reality affects business, all it takes is one meeting with company auditors or a regulatory visit.

Making Informed Choices

For routine chemical work, the 97-98% purity range saves money. For pharma or high-value research, the 99% mark saves time and stress. Before hitting “purchase,” most researchers check specification sheets, double-confirm impurity profiles, and remember that a little due diligence up front often spares months of frustration. Quality may come at a higher ticket price, but the real cost of a bad batch shows up as spoiled experiments, missed deadlines, and wasted careers.

The Case for Smart Storage

2-Chloroethyl-benzene doesn’t belong on an ordinary warehouse shelf or in a corner of the back lot. This chemical brings flammability and toxicity concerns. Most workers wouldn’t spot a problem just by looking at a drum, and risky storage can go bad without warning. Combustion and leaks become real dangers in hot or cramped areas. I remember a small industrial spill from another aromatic compound; the cleanup cost and air quality impact stretched on for weeks. Preparation makes the difference between safety and emergency calls.

Cool, well-ventilated rooms with reliable containment keep people, wildlife, and property protected. Upstairs spaces exposed to sunlight or heat sources, including boilers and lamps, should stay clear. Metals like steel or hard plastics, with tight-fitting lids, make the best containers, since cardboard softens and weakens if vapor collects. Those who ignore chemical compatibility run the risk of dissolved containers or worst, unwanted reactions. United Nations certifications or DOT-approved containers aren’t just red tape — serious standards help prevent flash fires or leaching hazards.

Security and Labeling Matter

Anyone who’s spent time in a busy loading bay knows how easy it is for unlabeled drums to get shuffled or knocked over. Clear, weatherproof labels with chemical names and hazard statements save confusion during hurried or stressful moments. Spill kits and self-closing valves within easy reach stop problems from spreading. Locked storage rooms keep the curious or uninformed away, and periodic inspections build trust within work crews.

Building policies based on OSHA’s Hazard Communication Standard can save headaches later. I’ve witnessed supervisors hesitate because they lacked up-to-date Material Safety Data Sheets. Training teams to read those sheets and spot the signs of vapor exposure gives everyone a stake in staying safe.

Clean Transportation Every Step of the Way

Getting chemicals from one point to another should feel routine, not adrenaline-filled. Trucks, railcars, and shipping containers take on extra value when drivers and handlers know the risks they carry. Loading 2-chloroethyl-benzene means strapping it down far from oxidizing agents, strong acids, or anything with a low flash point. Spill-proof bins with thick liners keep minor incidents from becoming emergencies.

It’s tempting to cut costs by packing trucks extra tight or using old containers, but those shortcuts often backfire. Laws require placards and documentation for a reason — not just fines, but so local firefighters and hazmat crews recognize the cargo if disaster strikes. I once watched an operator lose half his shipment to a low-speed collision; the paperwork sped up the local response and probably prevented a major environmental impact.

The Value of Emergency Planning

Staying ahead of risk means regular drills and debriefings. Even small companies benefit from mock spill scenarios and evacuation walkthroughs. Document contact info for medical aid and environmental agencies; those relationships help turn a crisis into a contained event.

Some say these steps seem like overkill. After years in the field, having watched a single careless act spiral, I know the real cost of complacency. Responsible handling of 2-chloroethyl-benzene doesn’t just protect profit, it safeguards lives and local ecosystems.